In the distant past within the first 12 miles of railroad west of Sheridan, Wyoming there were at least six coal mines that I know of. Some coal mines were active even before the CB&Q got here in 1890. Horse wagons were used to haul the coal into town. During the first two decades of the 1900s several towns were located near these mines that supported them. Most of the mines and their towns were gone by 1940 and the end of the Great Depression. The mines were originally all underground mining operations. Those that survived into World War II had converted to surface mining. Kiewit, Wyoming

When I arrived on the scene in 1975 only one mine remained, Peter Kiewit's Bighorn Coal Company. It is located about 8 miles west of Sheridan at a place the railroad calls, fittingly enough, Kiewit. Originally there was an industry siding next to the main opposite the tipple. (Dashed Red line on the diagram). The pullout track from the lower tipple yard and the lead from the upper tipple yard connected to this siding. In the late 1970s Bighorn coal joined the coal boom in the Powder River Basin and began loading unit coal trains. A two+ mile "siding" was built parallel to the twisting BN mainline through the Goose Creek canyon. (Blue on the diagram). This "loadout track" had to be more or less level for the early unit train Pacesetters to work properly. So it cut through a knob that the main and original siding went up and over. The tipple leads were then connected to this new unit train loadout track since they could no longer access the original siding and the siding was removed. Since the new unit train loadout track had to be level, the descending BN main drops below the loadout track begining just west of the east switch. It reaches its lowest point one mile from there. At that point the loadout track is a couple of hundred feet away from the main and it was at that point that Bighorn Coal built a modern, continuous loading, unit train tipple and an immense concrete silo in the late 1970s. At that point the main begins a steep 1.25% climb up over the aforementioned knob and soon regains the lost altitude. It goes on to climb above the level of the new loadout track. At the "summit" of this knoll a switch leads off the southside of the mainline and a sidetrack runs downhill next to the main to the Tongue River Stone company's loadout. We call that "the ballast pit" because the CB&Q and the BN used to get ballast from there. As the mainline decends from the knoll it again comes even with Bighorn Coal's level loadout track and the west switch is located there.

This photo was taken from the switch engine while pulling the rock loads from the ballast pit. The view is looking west. The track immediately to the right is the mainline. The main is descending from the knoll at this point and between the mainline curves you can see the west switch of the new loadout track. The loadout track just about dissappears in the weeds.

The new unit train tipple and silo was only used for about 6 years. At least that is my best guess based on my memory. We loaded several unit coal trains a week, sometimes two a day, at that tipple for several years. When CTC was installed through here a CTC control point with a power switch was installed at the east switch of the load out track. The west switch never did get a CTC switch, it remains hand operated to this day. Just after CTC came through, the unit train loadings at Bighorn were tapering off and soon the new tipple and its silo sat idle after about 1986? The "new" tipple and silo were finally torn down in the fall of 1999. The load out track and its east CTC switch remain at present.While the new tipple, silo, and loadout track raced into the future like the rabbit, then expired at a young age, the old tipple just plodded along tortoise-like and survived into the 21st century. I'd guess the old tipple dates from the 1940s, perhaps even the 1930s. It is a large corrugated steel building housing the coal cleaning and screening equipment. This old tipple is suspended over the top of the 5 tipple tracks. A small 5 track yard is on the high side immediately east of the tipple. West of the tipple the 5 tracks converged into one which then passes over a track scale. Below the scale the single track fans back out into 4 stub end tracks for the loaded cars. Men release the handbrakes on empty cars in the upper yard and gravity rolls the cars under the tipple. After loading, a man again operates the handbrake to roll the car down across the scale then into one of the stub tracks.

It was quite an operation back in the 1970s. We had a regular mine run job that went to work every morning 5 or 6 days a week at Sheridan. We'd haul 50 or so empty coal cars out there and spot the 5 upper tracks. Then we'd hang around until they got about 35 or 40 loaded and drag them back into Sheridan where we'd eat lunch. After lunch we'd take another 30-40 cars out and once again spot the 5 track upper tipple yard. In the late afternoon we'd gather up another 35-40 loads from the lower yard and drag them back into Sheridan.

The usual power was a single SD9.I really liked working that job. It was a very steep pull from the lower yard up to the original siding. One of the joys I get out of being an engineer is trying to get the absolute most out of a locomotive. Dragging 10 or 12 coal loads up that grade taxed an SD9 pretty well. I used to talk the conductor into latching onto 13 or 14 cars and believe me you really had to work your engine to get those up to the siding. I hadn't worked the mine run for several weeks but then one morning I got called for it off the extraboard. We gathered up our empty hoppers and headed for the mine. There we spotted up the 5 tipple tracks then went down to the scale house to await some loads. It was cold and we were sitting around the coal fired potbelly stove in the scale house shooting the bull with the weighmaster. Eventually a couple of tracks were full of loaded cars. The conductor got up to leave and asked me if I thought I could get all 12 cars in 2 track up the hill in one pull. I said yes.

The weighmaster snorted, "Hah, not with that gutless engine you won't".

I said "What is wrong with that unit?".

He said it has been on this job for two weeks and none of the crews could get more than 10 cars up the hill with it. He went on to say that several tried, stalled, and had to double out to the siding.

I said, "I'll get the 12 cars out alright, I've taken 14 up that hill before".

"Not with that engine you didn't", the weighmaster continued.

"Oh I've long thought that I could probably get 15 cars up it if conditons were right".

At that he beamed, "I'll bet you $20 you can't".

Now even way back in the late 1970s $20 was not a sum that would bankrupt a fella but it wasn't peanuts either. I am not a gambling man but this wasn't just gambling, he had insulted my engineerhood. I said, "If the conductor will latch onto 15 cars and kick all the handbrakes off you've got yourself a bet". The conductor asked if I really wanted to do that? I said yes but I want to pull them out of track 3. I didn't say why and the weighmaster didn't care what track I pulled from. Number 3 comes straight out and onto the steep lead without diverging through any switches and it has one less switch to navigate.

The conductor and brakemen walked down to the cars to lace them up and I got on the loco. I backed her up the lead to the siding switch at the top of the hill. At the top I stopped and started back down again with the sanders on. I worked a little throttle and kept about 10psi of independent brake on the unit as I went down the hill. Some of the powdered sand grit clings to the wheels and is carried under the brakeshoes scouring any gunk off the wheels. I nosed into #2 track and we pulled 3 loads out which we doubled to the 12 cars in #3. The brakey cut the air in and released the last of the handbrakes holding the cut. I waited until the main reservoir airpressure was back to normal before I started. With that many cars you don't want to stall on the hill without air in the cars because they will pull you back down and possibly right off the end of the stub tracks. I opened the throttle two notches then a third and released the independent. We didn't move. The SD9 was holding the cut from rolling down hill but it wasn't pulling it up. I went to number 4 and watched the ammeter. It climbed to about 800 amps and we began to creep backwards. Even though I had sanded the rails on the way down I turned on the sand to augment the crushed powder that was already there. As soon as we had moved a car length or so and had a couple of mph on them I went to #5. I could feel that subtle suddering in the frame that tells you she is right on the verge of slipping. I checked the ammeter, 850 amps. We picked up a couple of more mph and as the ammeter fell back a bit I went to throttle 6. The load climbed back to 850 amps. I noticed that several of the car droppers were standing outside the scale house with the weighmaster. I kind of figured that he and I didn't have an exclusive bet. I wondered what kind of odds they were giving on me? Our speed climbed some more and we were doing about 5 mph as the SD9 started onto the steep hill lead. I opened the throttle to number 7. The 567 series diesel engine was chanting deeply. Music to my ears. The ammeter climbed back to 850 then went right on to 855 and approached 860. I felt it in my butt first, before the ammeter dipped or the chant of the 567 lightened. I slapped the throttle down one notch but it didn't respond quick enough. The SD9 slipped. The wheelslip circuit detected the stumble and cut the load even more. I lost about 300 amps. The weighmaster was smiling. Damn! But with the throttle in #6 she quickly regained her footing. As we re-acceleratd I held off a little longer this time before going to number 7 again. With the slight additional speed this time the ammeter only climbed back up to 855 and she held. By the time we got to about 7 or 8 mph I opened the throttle to #8. The amps climbed back to 855 once more and the 567 was really talking to me. There is no sound more thrilling than a loco getting down on its knees at full load. Not only can you hear it, you can FEEL it. We had half the 15 cars on the hill now and the speed leveled out at about 9 mph. Up the lead we climbed with a cloud of sand dust swirling out from under the frame. As more cars came onto the hill the speed began to fall. I watched the ammeter climb back to 850 and towards 855. I felt the minute shuddering through my arm on the window rest and throuh my seat. She is about to stumble again. Unwilling to risk the loss of power accompanied by a detected wheelslip I dropped the throttle to 7. The SD9 kept on grinding up the hill. And the speed continued to fall. Once again the sound of the diesel and of the traction motor gears, the vibration, and the tension, reached that critical combination. So I dropped the throttle to #6. We continued up the hill. The speed continued to fall. Two more times we reached that edge that foretold of a wheel about to break free and two more times I dropped the throttle. Now we were in #4 and creeping along at about 3 mph. The loco & first car or two were up to where the grade lessens in preparation to join the siding. If I could stick her to the rail for another two carlengths we would have enough tonnage off the hill that we might just make it. We ground on. I felt that combo again and dropped the throttle to number 3 momentarily then right back to 4. But another slip was emminent, I dropped back to 3 and left it there. Just barely moving we now had the loco and 5 cars off the steepest part. Two more cars and we began to accelerate ever so slightly. Two more and we were really moving now at maybe 4 mph. With the loco now on the larger size rail of the siding I opened the throttle to 4 then 5 and we took off. By the time the last car came off the hill we were victoriously doing 8 or 9 mph in #8 throttle. I grabbed a bunch of air to stop the cut past the siding switch. Dang I was high. To an outsider it may seem silly or trivial but to me it sure is a boost when you know you got every ounce of tractive effort out of that locomotive. Yes sir it was a fine day.We shoved the cars up the siding to clear the mine lead. The conductor had a big grin on his face as he cut the engine off to return down the hill. I stopped the loco at the foot of the hill and got off. One miner met me at the ground and excitedly slapped me on the back. "Sonny I knew you could do it", he said excitedly. I gathered that he was the only one that had bet with me. He herded me along over to the scale house. I wasn't too sure I wanted to go there. A half dozen miners stood around the front door and none of them looked upon me with approving eyes. But the weighmaster handed me a twenty and shook his head. I hurried back to the engine.

So how come I could do it and none of the others could? I knew the answer to that question before I ever made the bet. During the post holiday lull in through freight business that came every January I would sometimes get set-back engineers as firemen on my trains. It didn't take very many times of observing how they tried to come up out of that hole to figure out why they can't pull anything. Most of them fit into one of two categories. Either they would just yank the throttle open to #8 and leave it there, letting the loco's wheelslip circuits handle the chores as they slip slide their way up the hill, or they would piddle around in the low throttles getting the cut started and then run out of speed and traction before reaching the top. Either way they could only handle 10 or 12 cars up the hill. To get more you have to do both. You must get the loco right up just under the slip point quickly to gain as much speed and momentum as possible before too many cars hit the hill. You must keep the loco at that maximum point as you go up so your rate of decelleration is at its minimum. Finally you must not be afraid to notch down as you lose speed. A throttled down loco that is holding the rail pulls more than one that is leaping about in higher throttles. I wasn't 100% certain that I could get 15 cars out of there but I knew how to give it a try.

Anyway as I said, the new tiple and silo came and went but the old one survived. The mine runs ended when the new tipple was built. What little coal was shipped from the old tipple could now be gathered up every few days by the Sheridan yard engine. Changes to union agreements now allowed yard engines to wander as far as 25 miles out of town to switch industries or to dogcatch trains. The old tipple continued to load coal through the spring of 2000. During sugar beet season in the fall, throughout the winter, and into early spring we would pull odd-lot coal from the stub tracks below the scale house. Coal for the sugar beet plants and coal for hospitals and colleges throughout the upper midwest as well as other small lot buyers. Bighorn coal maintained a thriving retail sales in lump and stoker coal which was loaded into semi-trucks near the scale house. By 1990 the tracks in the lower tipple yard were so bad that the RR would no longer allow us to go down there. The mine personel began pushing one car at a time up the hill with a large frontend loader. Since the new loadout track had cut down the size of the hill considerably they had no trouble doing this. They would leave the cars on the new loadout track to be picked up by the yard engine or a passing local freight. For the past decade the mine had not shipped any coal during the summer months so we were not surprised when we hadn't gotten any since spring of this year. The day I took that photo above of us pulling the ballast pit I thought the Bighorn coal tipple looked a little more ratty than usual. When we began to pull the rock cars from the ballast pit I turned around and took this photo of the Bighorn Coal tipple. They were begining to dismantle it. Spring of 2000 was the last time coal would be shipped from Bighorn Mine.

Bighorn Coal tipple looking east from the Ballast Pit. The mainline is in the forground and the "new" loadout track is out of sight down in the cut you can see in the weeds near the left side of the pic.

Bighorn Coal tipple looking northwest from mainline.

The track in the foreground is the "new" loadout track and the track branching off off it is the "Hill" track. The photo is taken from the cab of the yard engine sitting on the mainline. The "Hill" track used to come all the way up here and connect to the siding that occupied the gravel area in the bottom left corner foreground next to mainline. That was quite a bit higher than its present location in the photo.

Bighorn Coal tipple a few days later in the process of being dismantled August 16, 2000.

The cars in the photo are owned by Kiewit and are not safe for movement on the railroad. Most are ancient two pocket hoppers of CB&Q and UP ancestry and still have brass friction bearings. Most also still have their original roads' lettering. All 20 of them will be cut up for scrap over the next two months.As of late October, 2000, the tipple and cars are gone and the site is being reclaimed to a natural state. A part of track 5 in the upper tipple yard was left as a short spur and a small conveyor, fed by a truck dump, has been installed to load an occaisional car of coal.

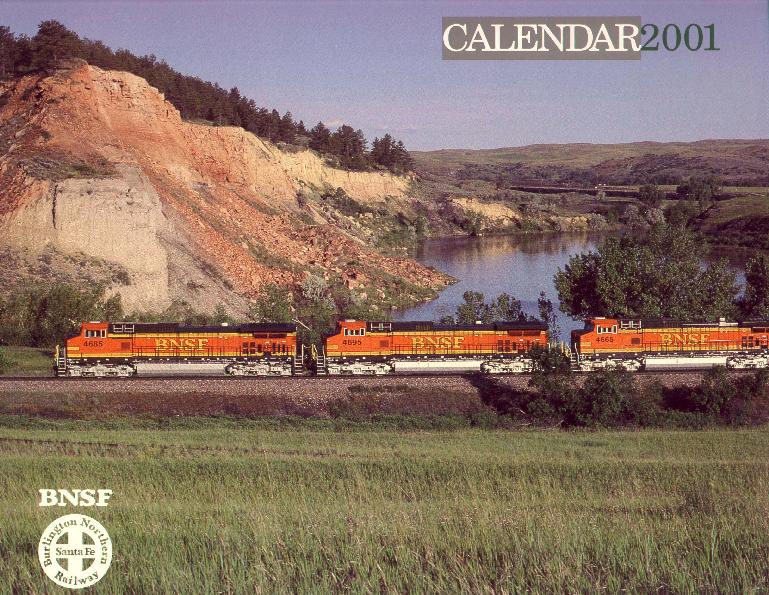

The "new" loadout siding has also been left intact. For what reason I do not know. It does provide access to the truck to RR car dump but seems excessive for that alone. There have been rumors that the BNSF would like to buy it for use as either a CTC siding or to store empty coal trains that normally plug Sheridan yard. I don't hold much hope for that but time will tell.The cover photo on the BNSF company calendar for 2001 is a photo taken at Kiewit. It doesn't show the tipple but is instead a view of HII C44s on an eastbound coal empty. Over the top of the train the view is across the "pond" formed by a wide spot in Goose Creek (actually it filled in an old mine). Beyond the pond you can see the black line of coal hoppers on the rear end of the train coming off the knoll. The old tipple was just beyond those cars. In the foreground at the bottom left of this picture you can see one rail of the "new" loadout track all but hidden in the grass between the BNSF 4685 and the BNSF company logo. Photo by Sheridan engineer Kirk Petty.

| Return to Tales index | My Home Page | E-Mail me |

Created 11-18-2000

Updated 12-15-2001